Overview

Brad Ortman is the Vice President of Operations, at Kokomo Grain, a grain company, with 8 locations across Indiana. As the VP of Operations for a state-wide cooperative, Brad has a lot on his plate. He’s always looking for new ways to simplify internal processes and improve operational efficiency.

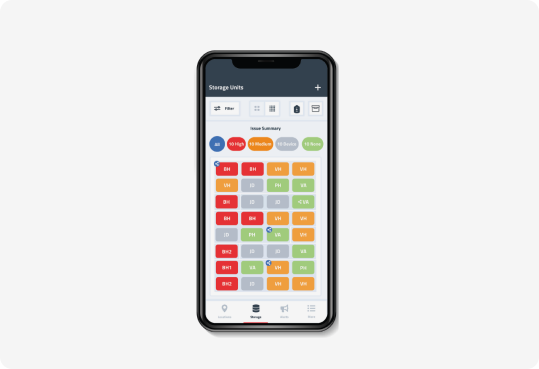

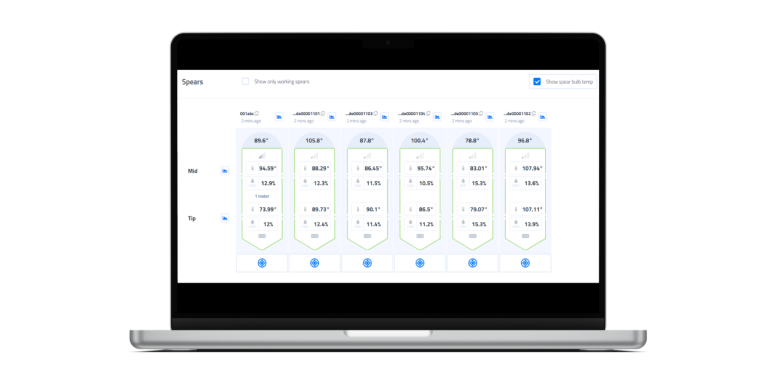

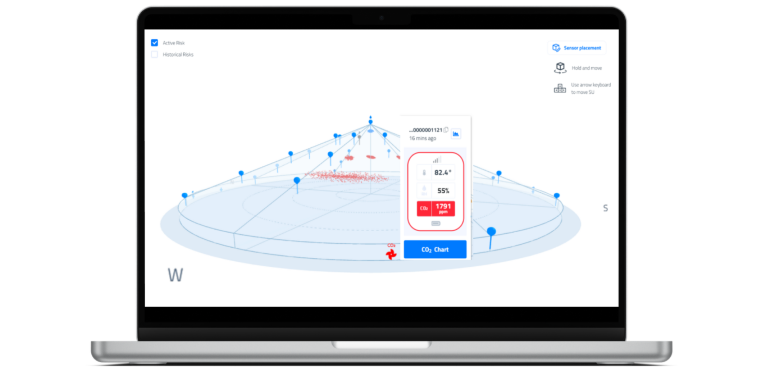

Kokomo grain has a storage capacity of 55 million bushels, split between bins, ground piles, and flat storage. One of their biggest challenges is monitoring and managing the quality of their stored grain. In the past, they have tried occasional probing for piles and cable monitoring systems for bins and flat storage. Over the years, Brad and his team began to recognize the limitations of these solutions:

Someone needed to visit the storage units to collect grain temp/moisture data. Every check took at least a couple of hours and involved a lot of effort.

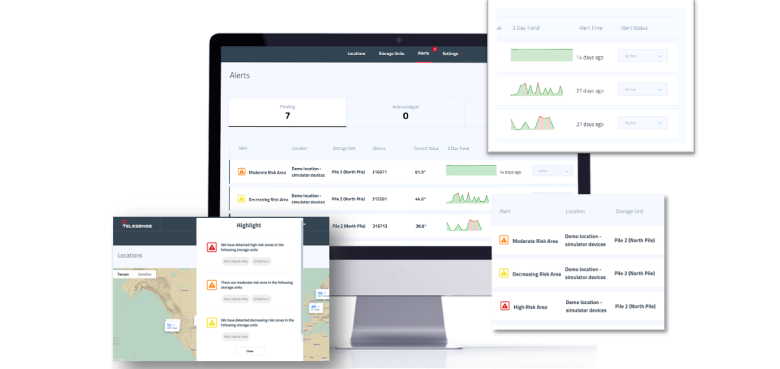

Occasional probing and cable systems made it difficult to get an instant view of what was happening in the grain.

Probes and cables monitored the grain in their vicinity and not the entire mass, so it was difficult to understand the source and extent of spoilage issues.

Guesswork involved in key decisions such as: - when to pick up the pile, from what side to begin unloading, and how to minimize spoilage.